Tromsø: The Subsea Storage Unit (SSU) is already patented, and prototype testing of parts of the system are underway. Kongsberg Oil and Gas Technologies are developing a storage system in cooperation with Statoil and Lundin, with financial support from The Research Council of Norway.

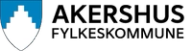

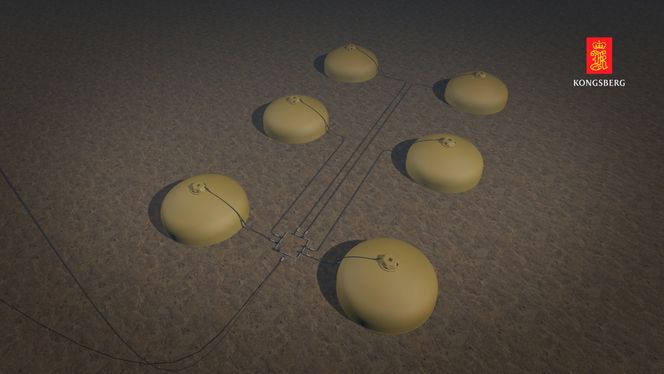

The below illustration depicts what Statoil has made of its 2020 dream, the Subsea Factory, a series of storage tanks with oval tops or domes, have been plotted. According to Kongsbergs concept, each is estimated to contain 25,000 cubic meters of oil and the diameter of each tank will be 40 meters.

Plans to expand the Johan Sverdrup oilfield in four stages by 2025More from tujobs:

Arctic waters

The subsea tanks will be emptied regularly via shuttle tankers. If the storage unit is located in the Arctic region, emptying will have to be planned during the ice-free season.

“We see this as an important contribution to Statoil’s subsea factory plans. It is also suitable in areas with harsh weather conditions, such as in the Arctic,” said the director of Kongsberg Oil and Gas Technologies’ subsea division, Trond Weberg, when the concept was presented at the Norwegian Subsea Symposium (Norsk Undervannssymposium) in Tromsø earlier this month.

He points out that the environmental aspect is important.

“There will be no emissions of volatile organic compounds or VOCs, as is common in the use of storage vessels. It is easy to operate and there is a low risk of accidents”, said Weberg.

Environmental Security

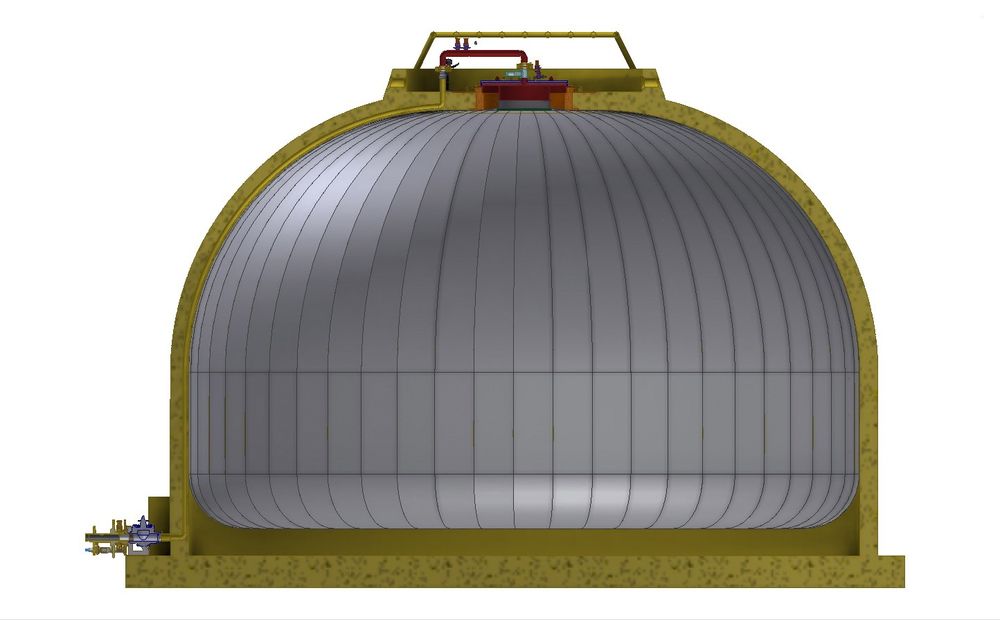

Protection against leakage is a priority. Double barriers will prevent oil spills.

The inner tank consists of a plastic sheet, developed by Swedish Trelleborg.

Tests of the material are currently underway to ensure their resistance to chemical erosion from the crude oil. The lifespan should be at least ten years.

The outer shell can be made of steel or concrete.

If there is a tear in the inner liner, the oil will be collected in the interior chamber. At the top there are several security systems and chambers to collect the oil. The cover is designed for the removal and insertion of a new container. Before the oil is pumped into the plastic container, the tank room will be filled with water. The oil in the container will then displace the water.

Weberg says that plastic containers for storage of fuel have been in use for many years, both in civilian and military situations. The same type of container has been used to transport water. They will withstand a drop of 1,000 meters without breaking.

More from tujobs:

Implementation and placement

Kongsberg has not yet concluded whether the dome or outer shell will be constructed of steel or concrete. Should it be made of steel, it must be ballasted or attached with a suction anchor due to buoyancy. A concrete cylinder will need anchoring.

Transport from the yard or construction site will be done by ship. An air filled tank can be towed out to the site and lowered into place.

A pilot model of the SSU should be ready within a year. In late 2017 or early 2018, the concept will be ready for full-scale realization.

How to extract oil from under Arctic ice

173,500 computerized mirrors provide 140,000 homes with power